Aerospace

Aerospace

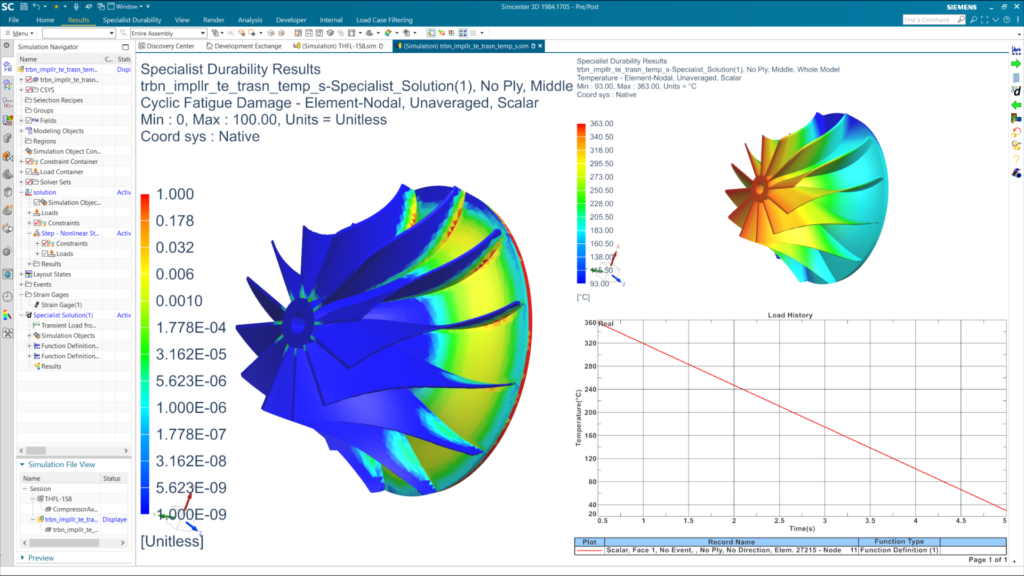

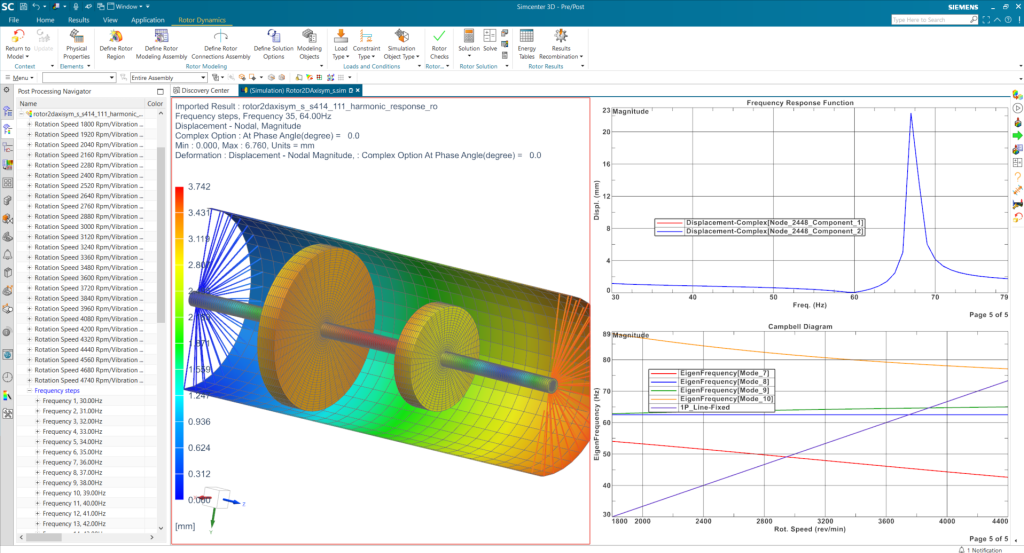

CAD/CAE/CFD technologies are integral to the modern aerospace industry, enabling engineers to design, analyze, and optimize aircraft and spacecraft with unprecedented precision and efficiency. The integration of CAD/CAE/CFD technologies is crucial for the aerospace industry to maintain its competitive edge and continue pushing the boundaries of flight and space exploration.

CADELL Technologies offer a wide range of Services to the Aerospace Industry: –

Cadell provides engineering solution to different segments and aerospace industry creating opportunity in a global market. As increasing competition, fluctuating fuel prices, mounting cost and varying currencies are forcing OEM and Tier suppliers to leverage the advantages of globalization by offshoring more work related to design and analysis. In the competitive market to have all the skills, tool knowledge and the domain knowledge is a tough task for any OEM and Tier suppliers also it makes more cost to the companies.