Chemical process equipment

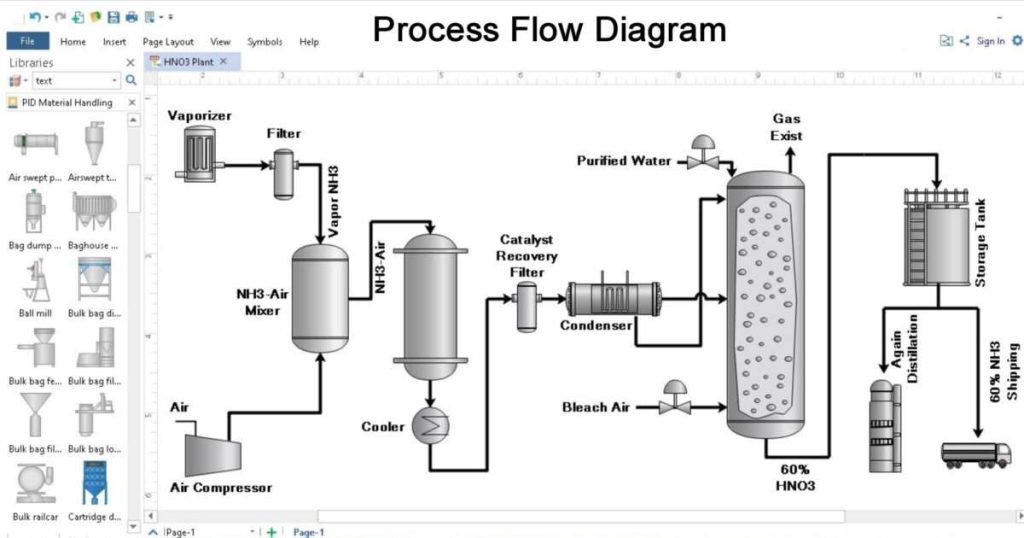

Designing chemical process equipment requires a deep understanding of chemical reactions, material science, thermodynamics, and fluid dynamics. It is a multidisciplinary field focused on creating safe, efficient, and reliable systems for transforming raw materials into valuable products.

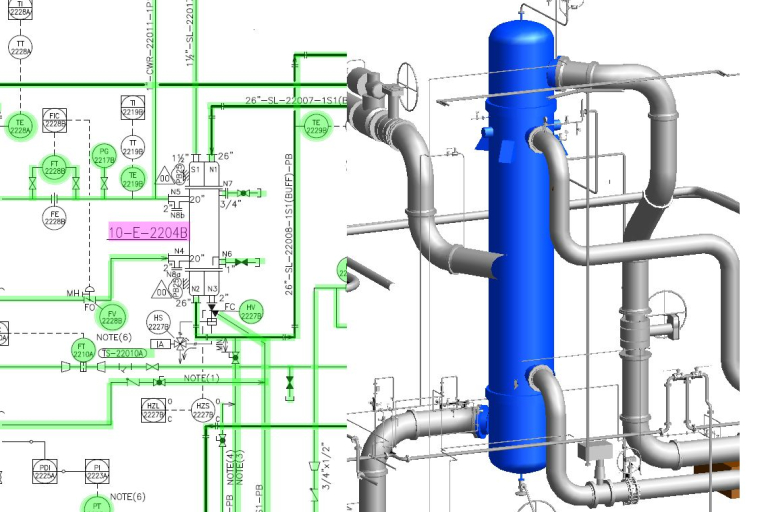

CADELL technologies have separate team of well experienced engineers who works continuously on designing of all type of equipment and for preparation of drawings for plant lay outs, equipment details for fabrication & piping. We also undertake consultancy on chemical process plant projects. CADELL technologies offer wide range of design & consultancy services to Chemical Process Equipment manufacturer.

We offer wide range of design & consultancy services on:

CADELL Capabilities on Design of all type of equipment:

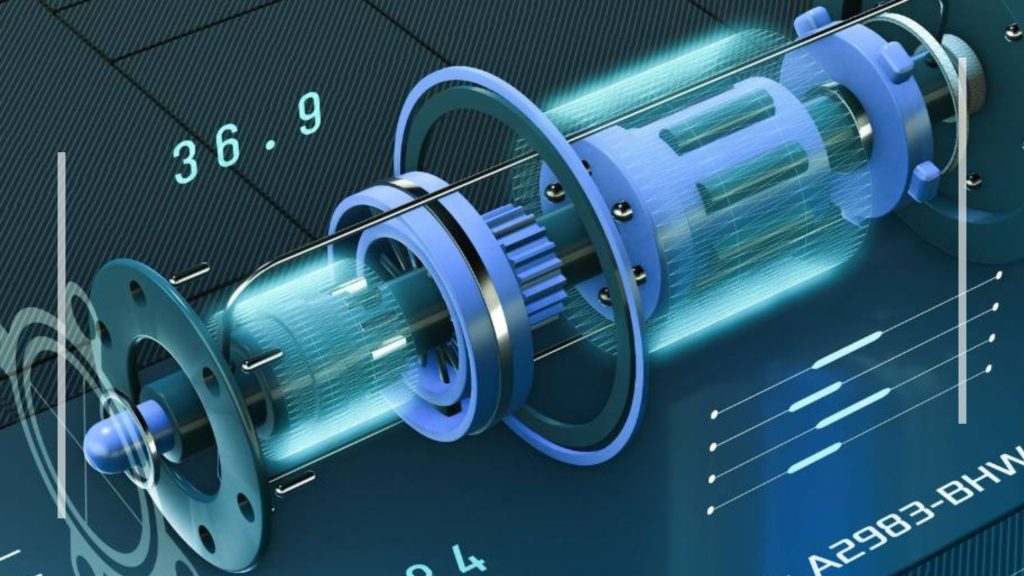

Process Plant and Pharmaceutical Equipment:-

Cadell also serve Process Plant and Pharmaceutical Manufacturing Industries in terms of design and manufacturing support.